BAG402

Medium to Ultra-High Vacuum Gauge

The INFICON single Bayard-Alpert Hot Ion Gauge BAG402 covers a wide measurement range from 5×10-10 mbar to 2.7×10-2 mbar (3.75×10-10 Torr to 5×10-2 Torr). Choose the INFICON BAG402 for affordable and repeatable process to base pressure measurements in a compact active gauge package. The unique, supported dual filaments offer superior accuracy, longtermstability and longevity.

Benefits

- Measurement range from 5×10-10 mbar to 2.7×10-2 mbar (3.75×10-10 Torr to 5×10-2 Torr)

- Excellent repeatability in the process pressure range from 10-8 … 10-2 mbar of 5%

- Overpressure detection protects the filament from premature burnout

- Two long-life yttrium oxide coated iridium filaments

- Automatic emission current selection reduces control complexity

- Easy to exchange sensing element with on-board calibration data guarantees high reproducibility

- RoHS compliance

Typical Applications

- Pressure measurement in semiconductor process and transfer chambers

- Industrial coating

- General vacuum measurement and control in the low to ultra high vacuum range

Part Number

| Part Number | Description |

|---|---|

| 353-600 | BAG402 DSUB9 KF25 |

| 353-601 | BAG402 DSUB9 CF40 |

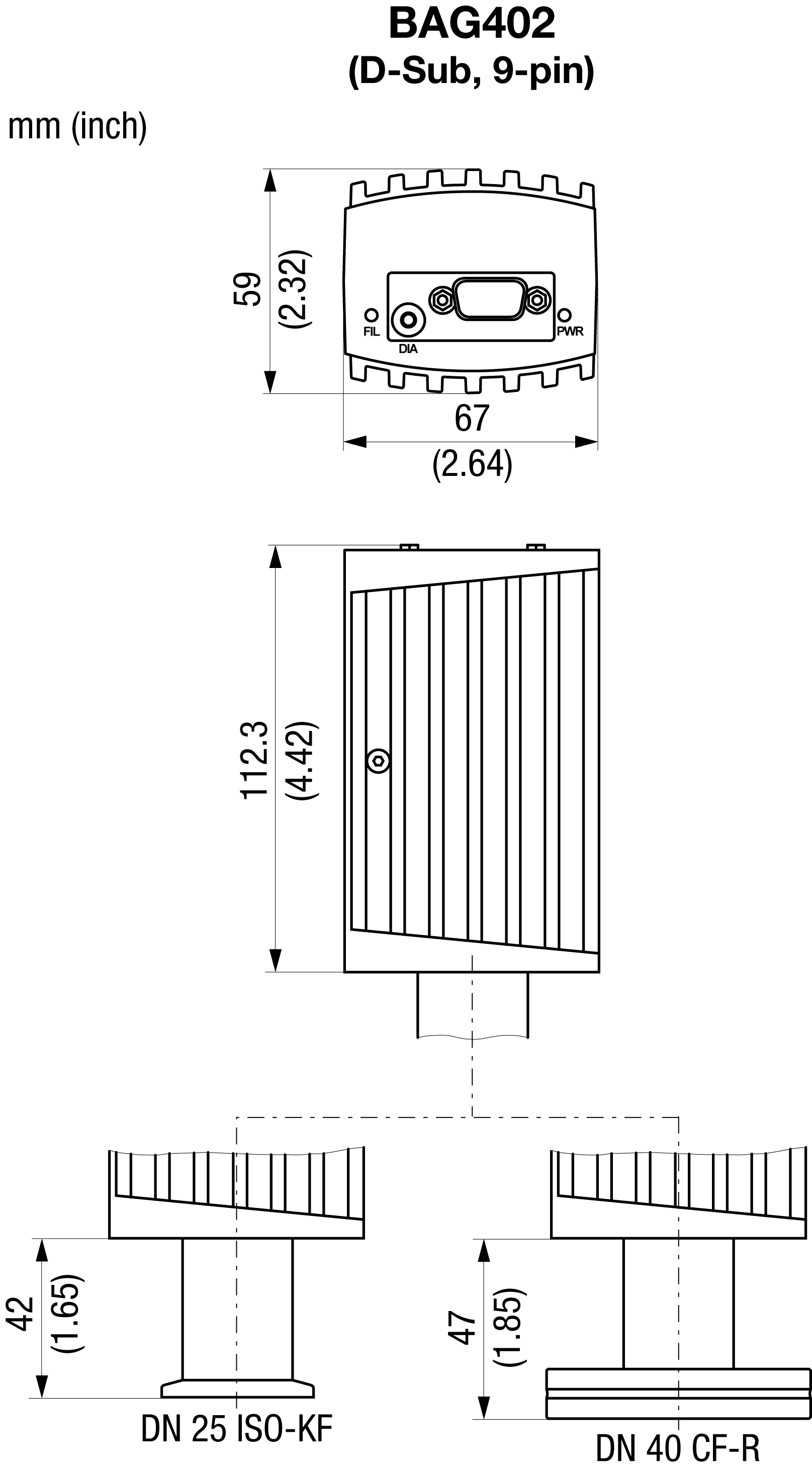

Dimensions

Specifications

| Type | BAG402 | |

|---|---|---|

| Measurement range (air, O2, CO, N2) | mbar | 5×10-10 … 2.7×10-2 |

| Accuracy | ||

| 10-8 … 10-2 mbar | % of reading | ±15 |

| Repeatability | ||

| 10-8 … 10-2 mbar | % of reading | 5 |

| Degas (1) | ||

| p < 7.2 × 10-6 | mbar | electron bombardment, max. 3 min |

| Pressure, max. | bar (absolute) | 2 |

| Temperature | ||

| Operation (ambient) | °C | 0 … +50 |

| Storage | °C | -20 … +70 |

| Bakeout at flange without electronics BPG402-S | °C | 80 |

| Supply voltage | +20 … +28 | |

| Output signal analog (4) | ||

| Output signal | V | 0 … +10 |

| Measurement range log / lin | V | 0 … +9 |

| Voltage vs. pressure | volts per decade | 1 |

| Error signal | V | > +10 |

| Load impedance, min. | kΩ | 10 |

| Secondary analog output | none | |

| Setpoint relay | ||

| Number of setpoints | none | |

| Range | ||

| Relay contact | ||

| Hysteresis | ||

| Contact rating | ||

| Digital functions | degas and emission | |

| Interface (digital) (2) | Diagnosis port | |

| Emission control | manual | |

| Filament | two Yttriumoxid (Y2O3) coated Iridium (Ir) | |

| Filament status / relay | LED / relay | |

| Electrical connection | D-Sub, 9-pin, male | |

| Cable length, max. | m (ft.) | 100 (330) |

| Materials exposed to vacuum | Y2O3, Ir, Pt, Mo, NiFe, NiCr, stainless steel, glass | |

| Internal volume KF / CF | cm³ (in.³) | 24 (1.46) / 34 (2.1) |

| Weight KF / CF | g | 450 / 710 |

| Degree of protection | IP30 | |

1) Reduced accuracy during degas

2) Simultaneous use of RS232C or VGC40x series controllers and Fieldbus is not allowed

Accessories

| Part Number | Description |

|---|---|

| 303-333 | Diagnostic cable 1.9m (P3) |

Spare Parts

| Part Number | Description |

|---|---|

| 354-484 | Spare sensor head BAG402 DN 25 ISO-KF |

| 354-485 | Spare sensor head BAG402 DN 40 CF-R |