Gemini MAG5xx MPG5xx

Gemini™ MxG5xx ATM to Ultra-High Vacuum Gauge

The INFICON Gemini™ Inverted Magnetron Vacuum Gauge is the workhorse for all vacuum measurement applications. While Gemini MPG50x combines two sensor systems in one small device to measure from atmosphere down to 1×10– 9 mbar, the Gemini MAG50x is a pure cold cathode sensor System (without Pirani element) which covers the range from 1×10-2 mbar to 1×10– 9 mbar. The patented ultra-low magnetic stray field design opens up a whole new range of applications. A unique interchangeable dual chamber sensor unit avoids cleaning cycles and reduces maintenance, making Gemini the most robust and economical vacuum gauge of its kind.

Gemini Cold Cathode and combination comes with fully integrated digital electronics, providing ultimate flexibility for system integration. The Cold cathode and Pirani combination version (MPG) option provides seamless transition, reliability, practicality and flexibility across wide ranging applications.

MAG and MPG Gemini are now available with EtherCAT fieldbus and setpoints as MAG55x and MPG55x.

For corrosive applications we suggest to use the ceramic coated version MxG5x4. Feedthrough and Pirani inside the sensor head are fully ceramic coated for enhanced corrosion resistance.

Gemini™ Cold Cathode and combination sensor`s come with fully integrated digital electronics, providing ultimate flexibility for System Integration.

Both, cold cathode and Pirani combination sensor Option provide seamless Transition, reliability, proactivity and flexibility across wide ranging applications.

Benefits

- Long lifetime in harsh environments

- Low magnetic stray field

- Reliable fast ignition

- Fastest maintenance – replaceable insert

- Compact size – easy to integrate

- Corrosion proof feed-through & sensor element

- Selectable measuring current

- 2 relay setpoints (in conjunction with MxG55x EtherCAT Version)

- EtherCAT and RS232/ RS485 digital interface

Typical Applications

- Base pressure monitoring and control, from atmosphere to high vacuum in evaporation and sputter coating applications.

- General vacuum measurement – industrial furnaces, architectural glass, semiconductor, refrigeration and air conditioning.

- Analytical and R&D applications – mass spectrometry, electron microscopes, medical, ophthalmic, optical and high energy physics.

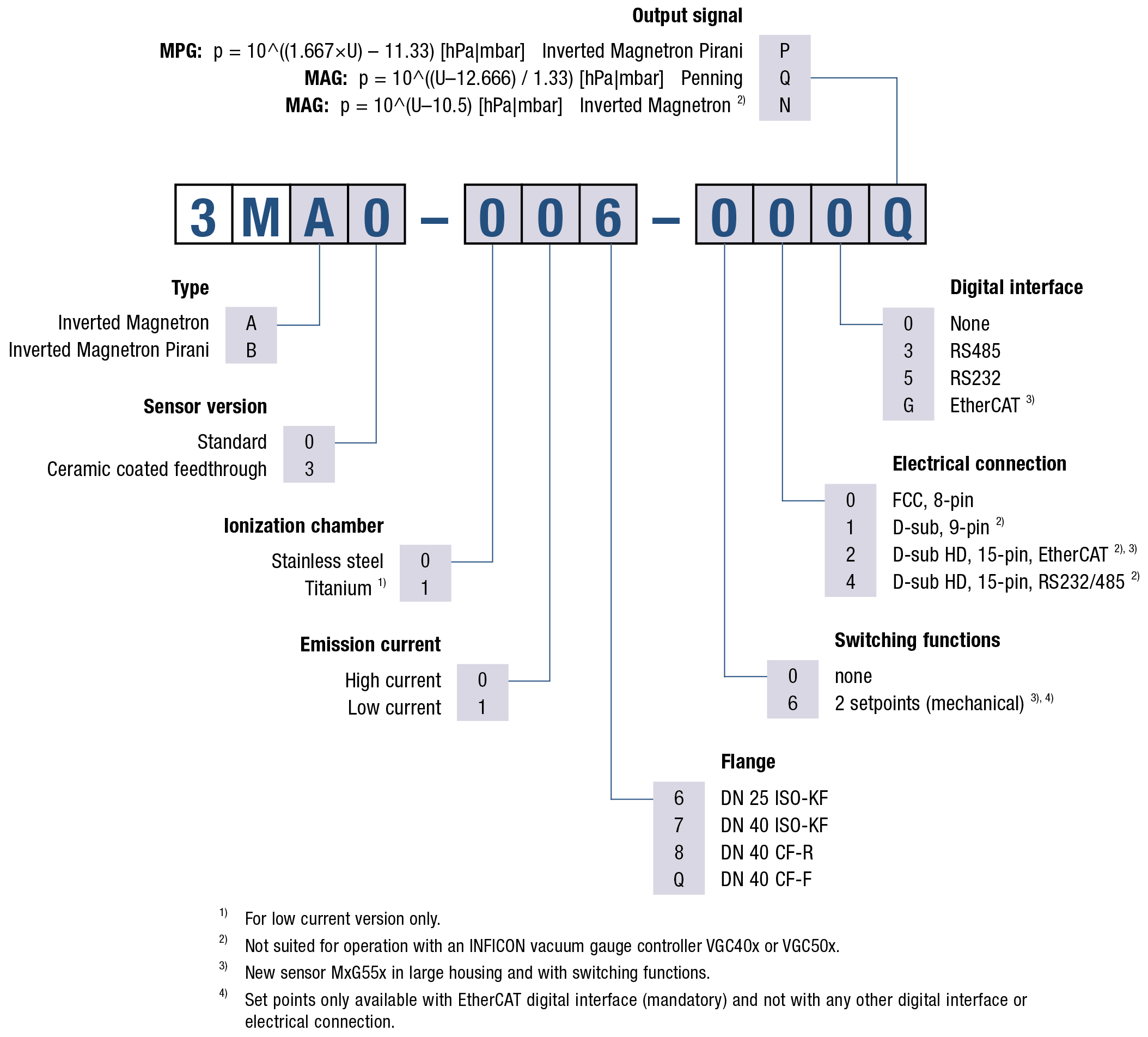

Part Number

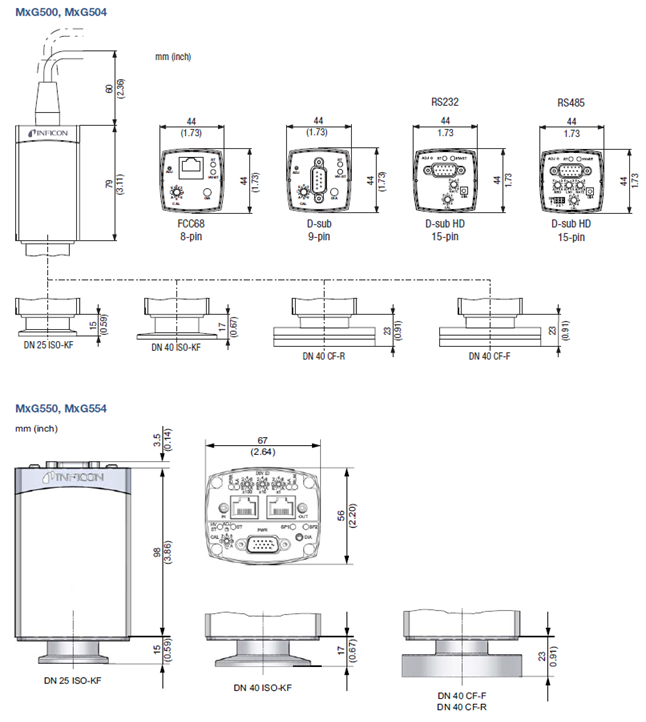

Dimensions

Specifications

| Type | MAG50x | MPG50x | |

|---|---|---|---|

| Measurement system | Cold cathode ionization measurement system (according to the inverted magnetron principle) | Pirani and cold cathode ionization measurement system (according to the inverted magnetron principle) | |

| Measurement range (air, N2) | mbar | 1×10-9 … 1×10-2 | 1×10-9 … 1000 |

| Accuracy (N2) | |||

| 1×10-8 … 1×10-2 mbar | % of reading | 30 | – |

| 1×10-2 … 100 mbar | % of reading | – | 30 |

| 100 … 1000 mbar | % of reading | – | 50 |

| Repeatability (N2) | |||

| 1×10-8 … 1×10-2 mbar | % of reading | 5 | – |

| 1×10-8 … 100 mbar | % of reading | – | 5 |

| Mounting orientation | any | any | |

| Admissible pressure | bar (absolute) | 10 (limited to inert gases <55°C) | 10 (limited to inert gases <55°C) |

| Admissible temperature | |||

| Operation (ambient) | °C | +5 … +55 | +5 … +55 |

| Bakeout at flange (1) | °C | <150 | <150 |

| Storage | °C | -40 … +70 | -40 … +70 |

| Filament temperature | °C | – | 120 |

| Relative humidity for 30 days a year | |||

| 1×10-7 … 1×10-2 mbar | % | <95 (non-condensing) | <95 (non-condensing) |

| 1×10-8 … 1×10-2 mbar | % | <70 (non-condensing) | <70 (non-condensing) |

| Supply voltage | |||

| At gauge (2) | V (dc) | +14.5 … +30 | +14.5 … +30 |

| Ripple | V (p-p) | <1 | <1 |

| Power consumption | W | <2 | <2 |

| Fuse to be connected | AT | <1 | <1 |

| Voltage range | |||

| analog output | V | 0 … +10.5 | 0 … +10.5 |

| Measurement range | |||

| 3MAx-xxx-xxxN | V | <+0.5 | – |

| 3MBx-xxx-xxxP | V | – | – |

| 3MAx-xxx-xxxQ | V | +0.667 … +10 | – |

| Voltage vs. pressure | |||

| 3MAx-xxx-xxxN | volts per decade | 1 (logarithmic) | – |

| 3MBx-xxx-xxxP | volts per decade | – | – |

| 3MAx-xxx-xxxQ | volts per decade | 1.33 (logaritmic) | – |

| Error signal | |||

| 3MAx-xxx-xxxN | V | <+0.5 | – |

| 3MAx-xxx-xxxQ | V | <+0.3 | – |

| 3MBx-xxx-xxxP | V | – | – |

| Output impendance | Ω | 2 x 4.7 (short circuit-proof) | – |

| Load impendance | kΩ | >10 (short circuit-proof) | – |

| Step response time | |||

| p > 10-6 mbar | ms | <100 | <100 |

| p = 10-6…10-8 mbar | ms | ~1 | ~1 |

| Gauge identification (FCC connector gauges) | |||

| 3MAx-0xx-000N | kΩ | – | |

| 3MAx-0xx-000Q | kΩ | 100 | |

| 3MBx-0xx-000P | kΩ | – | |

| Status signal, digital output (FCC connector) | |||

| Current rating | mA | 100 (sink) | |

| High Voltage is ON | V(dc) | +14.5 … +30 (depending on supply voltage) | |

| High Voltage is OFF | V(dc) | 0 | |

| Status signal, digital output (D-sub connector) | |||

| Supply voltage | V(dc) | <30 | |

| Current rating | mA | 100 | |

| High voltage ON | V(dc) | 0 | |

| High voltage OFF | open | ||

| Electrical connection | |||

| 3Mxx-0xx-000x | FCC68, 8-pin, female | ||

| 3Mxx-0xx-010x | D-sub, 9-pin, male | ||

| 3Mxx-0xx-04xx | D-Sub HD, 15-pin, male (for RS232/485 version) | ||

| 3Mxx-xxx-x2Gx | D-Sub HD, 15-pin, male (for EtherCAT Version) | ||

| Sensor cable | |||

| 3Mxx-0xx-000x | 8-pin, shielded | ||

| 3Mxx-0xx-010x | 9-pin, shielded | ||

| 3Mxx-0xx-04xx | D-Sub HD, 15-pin, male (for RS232/485 version) | ||

| 3Mxx-xxx-x2Gx | D-Sub HD, 15-pin, male (for EtherCAT Version) | ||

| Cable lenght | |||

| FCC connector cable | m | <50 (0.14 mm2/ conductor) | |

| High voltage (in the measuring chamber) | |||

| Ignition voltage | kV | <4.5 | |

| Operating voltage | kV | <3.3 | <3.3 |

| Current (in the measuring chamber) | |||

| High current | µA | <380 | |

| Low current | µA | <130 | |

| Setpoint relays (MxG55x) | |||

| Range (N2) | mbar | 5×10-5 … 1500 | |

| Relay contact | normally open (NO), potential free | ||

| Hysteresis | % of threshold | 10 | |

| Contact rating of mechanical relays | V/A | <30/ <1 | |

| Switching time | ms | <30 | |

| Materials exposed to vacuum | |||

| 3Mx0-xxx-xxxx | Ni alloy, AI2O3, glass, stainless steels | ||

| 3Mx3-xxx-xxxx | Mo, AI2O3, stainless steels | ||

| 3Mx0-11x-xxxx | Ni alloy, Mo, Al2O3, glass, Ti, stainless steels | ||

| 3Mx3-11x-xxxx | Mo, Al2O3, Ti, stainless steels | ||

| Internal volume | |||

| DN 25 ISO-KF | cm³ | ||

| DN 40 ISO-KF | cm³ | ~20.9 | |

| DN 40 CF-F | cm³ | ~25.2 | |

| DN 40 CF-R | cm³ | ~25.6 | |

| Internal volume | cm³ | 22.8 | |

| Weight (MxG50x) | |||

| DN 25 ISO-KF | g | <280 | <280 |

| DN 40 ISO-KF | g | <320 | <320 |

| DN 40 CF-F & CF-R | g | <570 | <570 |

| Weight (MxG50x) | |||

| DN 25 ISO-KF | g | <280 | <280 |

| DN 40 ISO-KF | g | <320 | <320 |

| DN 40 CF-F & CF-R | g | <570 | <570 |

| Degree of protection | IP 40 | IP 40 | |

| CE conformity | |||

| RoHS | 2011/65/EU | ||

| EMC | 2014/30/EU, EN 61000-6-2, EN 61000-6-3, EN 61326-1 | ||

| Safety | EN 61010-1 | ||

| RS232C / 485C (MxG50x) |

|||

| Baud rates | kBaud | 9.6/ 19.2/ 38.4/ 57.6 | |

| Address | 2 switches (address 00 – 255) | ||

| Digital functions | Read pressure, select Units: Torr, mbar, Pa, micron, counts. Monitor gauge Status, detailed Alarm and warning Information, safe state allows Definition of behavior in case of error. | ||

| Connector for RS232 & RS485 | D-Sub HD, 15-pin, male | ||

| EtherCAT® (MxG55x) | |||

| Protocol | EtherCAT® | ||

| Communication standard | ETG.5003.1 S (R) V1.1.0 4) ETG.5003.2080 S (R) V1.3.0 5) | ||

| Node address | Explicit Device Identification | ||

| Physical layer | 100Base-Tx (IEEE 802.3) | ||

| Digital functions | Read pressure, select Units: Torr, mbar, Pa, micron, counts. Monitor gauge Status, detailed Alarm and warning Information, safe state allows Definition of behavior in case of error. | ||

| EtherCAT connector | 2 x RJ45, 8-pin (socket), Input & output | ||

| EtherCAT cable | Special Ethernet Patch cable or crossover cable, shielded (CAT5e Quality or higher). | ||

| Cable lenght | m | <100 | |

1) Without electronics.

2) The minimum voltage of the supply unit must be increased proportionally to the length of the sensor cable.

3) Cold cathode ignited.

4) Semiconductor Device Profile

5) Specific Device Profile: Vacuum Pressure Gauge

Accessories

| MAG5xx | |

|---|---|

| Part Number | Description |

| 211-098 | Centering ring with fine filter DN 25 KF |

| 351-550 | MxG50x Ignition tool set |

| 211-113 | Centering ring with baffle DN 25 KF |

| 353-512 | Baffle for BPG400 |

| MPG5xx | |

| Part Number | Description |

| 211-098 | Centering ring with fine filter DN 25 KF |

| 351-550 | MxG50x Ignition tool set |

| 211-113 | Centering ring with baffle DN 25 KF |

| 353-512 | Baffle for BPG400 |

Spare Parts

| MAG5xx | |

|---|---|

| Part Number | Description |

| 351-500 | MAG500 spare sensor, 25KF, SS |

| 351-556 | Spare ion chamber TI |

| 351-512 | MAG500 spare sensor, 40KF, SS |

| 351-536 | MAG500 spare sensor, 40CF-R, SS |

| 351-524 | MAG500 spare sensor, 40CF-F, SS |

| 351-502 | MAG500 spare sensor, 25KF, TI |

| 351-514 | MAG500 spare sensor, 40KF, TI |

| 351-538 | MAG500 spare sensor, 40CF-R, TI |

| 351-526 | MAG500 spare sensor, 40CF-F, TI |

| 351-501 | MAG504 spare sensor, 25KF, SS |

| 351-513 | MAG504 spare sensor, 40KF, SS |

| 351-537 | MAG504 spare sensor, 40CF-R, SS |

| 351-525 | MAG504 spare sensor, 40CF-F, SS |

| 351-503 | MAG504 spare sensor, 25KF, TI |

| 351-515 | MAG504 spare sensor, 40KF, TI |

| 351-539 | MAG504 spare sensor, 40CF-R, TI |

| 351-527 | MAG504 spare sensor, 40CF-F, TI |

| 351-995 | MxG40x/50x Spare parts ignition aid (10) |

| 351-555 | Spare ion chamber SS |

| MPG5xx | |

| Part Number | Description |

| 351-506 | MPG500 spare sensor, 25KF, SS |

| 351-518 | MPG500 spare sensor, 40KF, SS |

| 351-542 | MPG500 spare sensor, 40CF-R, SS |

| 351-530 | MPG500 spare sensor, 40CF-F, SS |

| 351-508 | MPG500 spare sensor, 25KF, TI |

| 351-520 | MPG500 spare sensor, 40KF, TI |

| 351-544 | MPG500 spare sensor, 40CF-R, TI |

| 351-532 | MPG500 spare sensor, 40CF-F, TI |

| 351-507 | MPG504 spare sensor, 25KF, SS |

| 351-519 | MPG504 spare sensor, 40KF, SS |

| 351-543 | MPG504 spare sensor, 40CF-R, SS |

| 351-543 | MPG504 spare sensor, 40CF-F, SS |

| 351-509 | MPG504 spare sensor, 25KF, TI |

| 351-521 | MPG504 spare sensor, 40KF, TI |

| 351-545 | MPG504 spare sensor, 40CF-R, TI |

| 351-533 | MPG504 spare sensor, 40CF-F, TI |

| 351-995 | MxG40x/50x Spare parts ignition aid (10) |

| 351-555 | Spare ion chamber SS |

| 351-556 | Spare ion chamber TI |