Augent OPG550

Optical Plasma Vacuum Gauge

The INFICON AugentTM Optical Plasma Gauge is a compact and intelligent solution for vacuum monitoring. AugentTM combines two sensor technologies into one compact device for gas type monitoring from 1 x 10-7 to 5 mbar and to measure total pressure from 1 x 10-7 mbar to atmosphere at the same time. AugentTM is protected by an integrated Pirani sensor to switch off plasma above 20 mbar. The fast optical measurement principle allows the detection of in principle any type of gas.

Benefits

- High speed leak detection allows chamber leak test

- Increase of productivity and yield

- Long life time, no filament burns, air inrush protection

- Withstand process chemistry

- Smart algorithm for easy integration

- Compact design and small footprint

- Reliable and fast start up

Typical Applications

- Chamber leak check, faster RoR (rate of rise) test

- Leak check to find internal leaks from gas supply lines

- Real time end point control

- Gas type and concentrations control

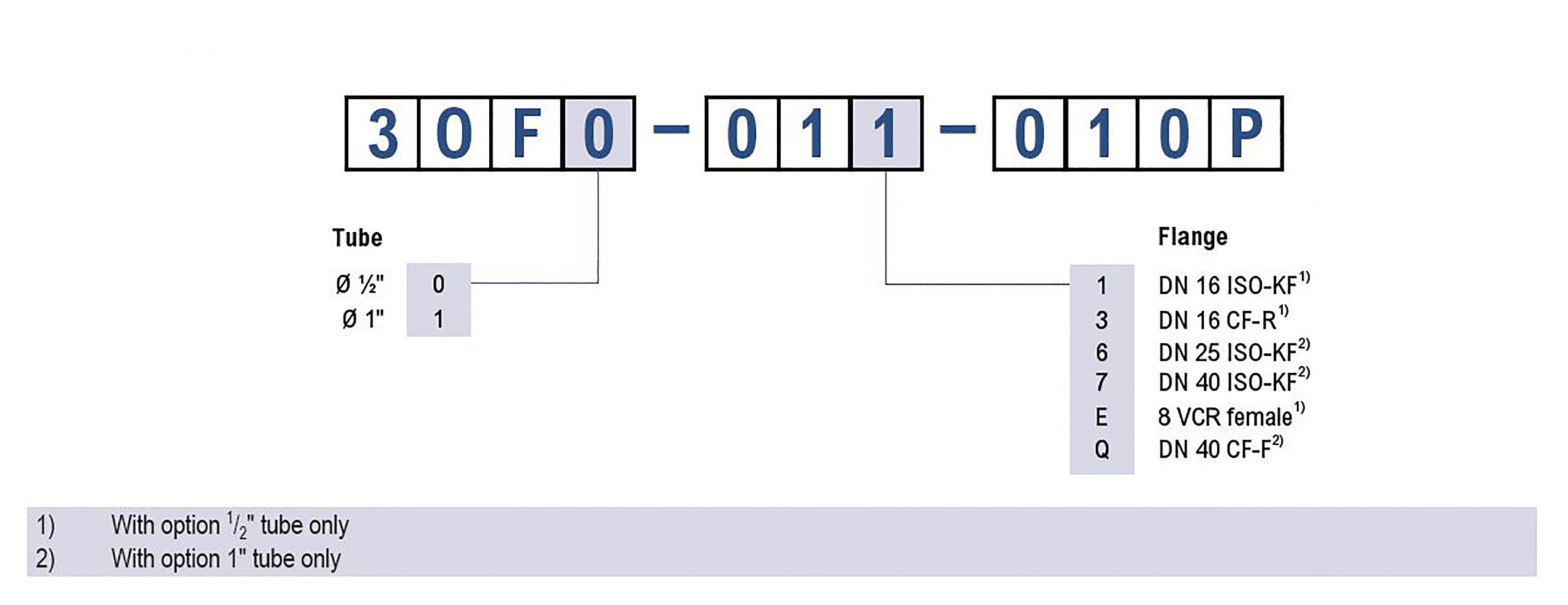

Part Number

| Part Number | Description |

|---|---|

| 3OF0-001-010P | OPG550 9DSub, 16-KF |

| 3OF0-003-010P | OPG550 9DSub, 16-CF-R |

| 3OF0-006-010P | OPG550 9DSub, 25-KF |

| 3OF0-00E-010P | OPG550 9DSub, 8-VCR f |

| 3OF0-011-010P | OPG550 TI,LC,9DSub,16KF |

| 3OF0-013-010P | OPG550 TI,LC,9DSub,16CF-R |

| 3OF0-01E-010P | OPG550 TI,LC,9DSub,8-VCR f |

| 3OF1-016-010P | OPG550 TI,LC,9DSub,25KF |

| 3OF1-017-010P | OPG550 TI,LC,9DSub,40KF |

| 3OF1-01Q-010P | OPG550 TI,LC,9DSub,40CF-F |

Specifications

| Type | OPG550 | |

|---|---|---|

| Measurement system | Cold Cathode according inverted magnetron principle and Thermal conductivity according Pirani principle | |

| Measurement range N2 | 1×10-7 … 5 | |

| Detection limit 25 liter chamber | ||

| O2 leaks in pressure rise method | mTorr/min | >0.3 |

| O2 leaks during pump down from atmosphere with N2 backfill | mTorr/min | >1 |

| Accuracy total pressure reading N2 | ||

| 1 x 10-7 … 100 mbar | % of reading | 30 |

| 100 … 1000 mbar | % of reading | 50 |

| Repeatability total pressure reading N2 | ||

| 1 x 10-7 … 100 mbar | % of reading | 5 |

| Pressure | ||

| Limited to inert gases < 50°C | bar (absolute) | <10 |

| Temperature | ||

| Operation (ambient) | °C | +5 … +50 |

| Storage | °C | -20 … +70 |

| Bakeout at flange with electronic unit | °C | <80 |

| Bakeout at flange w/o electronic unit | °C | <120 |

| Relative humidity for 30 days a year | ||

| Humidity | % | <95 (non-condensing) |

| Supply voltage | ||

| At gauge | V (dc) | +14.5 … +30 |

| Ripple | V (p-p) | <1 |

| Power consumption | W | <5 |

| Fuse to be connected | AT | 1 |

| Output signal | ||

| Analog | V (dc) | 0 … +10 |

| Digital | Digital | RS232C |

| Electrical connection | D-Sub, 9-pin, male | |

| High voltage (in the measuring chamber) | ||

| Ignition voltage | kV | <4.5 |

| Operating voltage | kV | <3.3 |

| Materials exposed to vacuum | ||

| General | General | Al2O3, Stainless seel 1.4435 |

| Anode | Anode | Molybdenum |

| Ionization chamber | Ionization chamber | Titanium, stainless steel 1.4016 |

| Ignition aid | Ignition aid | Stainless steel 1.4310 |

| Vacuum flange | ½ in. tube (spiral baffle):

DN16 ISO-KF, DN16 CF-R, 8-VCR female

1 in. tube (standard baffle): DN25 ISO-KF, DN40 ISO-KF, DN40 CF-F |

|

| Internal volume | cm³ (in.³) | < 46 (2.81) |

| Weight | g | <700 |

| Dimensions | ||

| Footprint | mm | 68 x 68 |

| Height | mm | < 154 |

| Protection type | IP40 | |

| Standards | CE | |